If you think autosport is just about drivers pushing the limits, you’re missing half the story. The real magic happens in the garage where engineers fine-tune every bolt and sensor. That’s the world of auto sport engineering, where technology, smarts, and relentless problem-solving create the fastest cars on the planet.

These days, winning by instinct isn’t enough. Teams rely on hundreds of data points from the car. Tire pressures, brake temps, how the wind hits a spoiler—engineers have eyes everywhere. Even a tiny improvement in downforce or a slick bit of coding in the car’s electronics can make all the difference in that final lap. If you ever wondered why modern racing looks almost surgical, it’s because the cars are rolling evidence of engineering obsession.

But here’s the catch: more tech means the tiniest mistakes get punished hard. One miscalculated tweak, and a million-dollar machine can end up crawling at the back. That pressure means there’s never a boring day in the world of autosport engineering. If you’re thinking about a future in this field (or you just want to impress your friends with facts), understanding the basics is where it all starts.

- What Is Autosport Engineering?

- Key Innovations That Changed Racing

- The Team Behind the Tech

- Getting Started in Autosport Engineering

What Is Autosport Engineering?

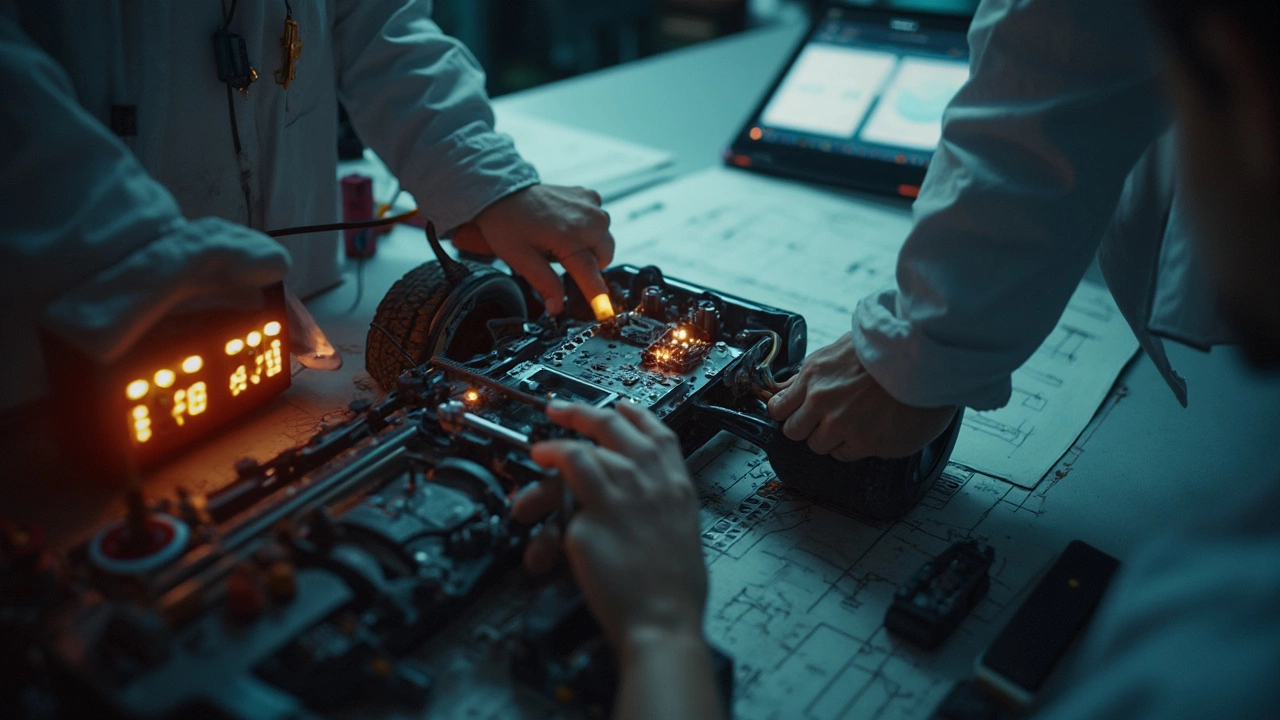

Auto sport engineering is the nuts-and-bolts behind speed and safety in the racing world. It’s a hands-on mix of mechanical engineering, electronics, materials science, computer coding, and more—basically, it’s everything about how race cars are built, tested, and made faster or tougher for real competition.

Unlike general car engineering, this stuff is all about making every microsecond count. While normal road cars aim for comfort and reliability, autosport engineering is about wringing out the max performance and keeping drivers safe even when things go sideways at 200 mph. Think of it as the brains turning a wild machine into a controlled missile. These engineers obsess over everything from suspension geometry to aerodynamics to getting more power out of tiny engines without blowing them up mid-race.

Here’s what this field covers in real life:

- Designing and building the chassis so it’s light but doesn’t fold in a crash.

- Tweaking the aerodynamics so the car sticks to the road and not the air.

- Developing engines and transmissions to squeeze out every last horsepower.

- Installing sensors and electronics to catch problems the moment they show up.

- Working with real-time data during races to adapt to weather, tire wear, or driver feedback.

If you’re into numbers, check out how different elements stack up in a typical Formula 1 car:

| Feature | Formula 1 Car (2024) |

|---|---|

| Top speed | Up to 226 mph (364 km/h) |

| Horsepower | Approx. 1,000 hp |

| Chassis weight | 798 kg (including driver & fluids) |

| Sensors per car | Over 300 |

| Downforce generated | Up to 3,600 kg at full speed |

No surprise—autosport engineers don’t do this alone. Teams include designers, data analysts, even computer programmers who write code to tune the car on the fly. With every race, the cars—and the people making them—adapt, tweak, and improve nonstop.

Key Innovations That Changed Racing

You want to know why modern racetracks are packed with drama? Look at the tech packed into every car. Some breakthroughs have totally flipped the game. Here’s what really mattered, not just in the past but still today.

- Auto sport engineering brought aerodynamics into the mainstream in the late 1960s. Big rear wings and slick body shapes didn’t just look cool—they pushed cars tighter to the track, letting drivers corner faster. Teams like Lotus proved that smart use of airflow could outpace brute horsepower.

- Carbon fiber changed everything in the 1980s. Before that, cars were heavy, clunky, and dangerous in a crash. McLaren introduced the first carbon-fiber monocoque in Formula 1 in 1981, making cars both lighter and way stronger. Now, every top-level race car owes its survival—and speed—to carbon fiber.

- Data logging and computers hit hard in the 1990s. Back then, race engineers started plugging cars into laptops after every run, pulling data on engine performance, tire wear, and even how late a driver braked. Today, teams get real-time updates sent straight to the pit wall. A small error in tire pressure? The crew knows before the driver does.

- Tire science is a quiet hero. Modern race tires aren’t just rubber—they’re built for exact track temps and weather. Michelin and Pirelli dump millions into research, and teams pick compounds with care, sometimes swapping them at a moment’s notice to gain a half-second—that’s a lifetime in racing.

- Hybrid powertrains aren’t just for saving gas on your commute. In Formula 1, these systems allow cars to recover energy from braking or exhaust and pour it back into electric boosts for overtaking. It’s not just green tech; it’s straight-up performance.

Autosport isn’t static. If you’re in the pits or glued to the screen, the real story is in the details. The next headline innovation could be right around the corner, and the people behind them are always looking for an edge.

Getting Started in Autosport Engineering

Diving into auto sport engineering isn’t just about loving cars. You need practical skills and a plan. Most pros in this field started out studying mechanical, electrical, or even software engineering. Universities like Oxford Brookes, Cranfield, and the University of Stuttgart have motorsport engineering degrees with hands-on training and racing partnerships.

Just classroom work won’t get you far. Real-world experience is a must. Join your school’s Formula Student or Formula SAE team—almost every top engineer in autosport mentions it in their resume. Teams build and race cars from scratch, learn project management, and face deadlines that feel like the real pit lane. Want another shortcut? Volunteer at local racing events, shadow mechanics, or grab an internship with a race shop, even if you’re just sweeping floors or fetching coffee. That foot in the door is how legends have started.

- Take math and physics seriously—race teams spot problems using calculations, not gut feelings.

- Practice CAD (Computer-Aided Design)—software like SolidWorks or CATIA is the backbone of modern car design.

- Get to know data analysis tools like MATLAB or RaceLogic’s software. Race teams use these to squeeze extra tenths out of a lap time.

- Work on your communication skills. In autosport, you need to explain complex problems to drivers, mechanics, and sponsors who don’t care about jargon.

Check this quick look at some real numbers inside the industry:

| Experience/Qualification | Average Entry-Level Salary (2024, USD) |

|---|---|

| Intern (motorsport team) | $27,000 |

| Bachelor’s degree (mechanical/electrical/software) | $42,000 |

| Motorsport grad program (1-2 years’ experience) | $54,000 |

It isn’t just about salaries; it’s the thrill of seeing something you built powering down the straight. If you stick with it—picking up code, electronics, and people skills along the way—autosport engineering can turn tinkering in a garage into a job you’ll never want to leave.

Bennett Kincaid

Hi, I'm Bennett Kincaid, an accomplished sports enthusiast with a passion for motorsports. I've been following the world of racing for over a decade, and I love sharing my insights and experiences with fellow fans. My expertise in sports allows me to understand the intricacies of the game and provide in-depth analysis. When I'm not attending races or writing about them, you can find me coaching local youth sports teams or enjoying a pick-up game with friends. My ultimate goal is to continue fostering the growth of motorsports and inspiring the next generation of athletes.

view all postsWrite a comment